OEM Contract Manufacturing

OEM Contract Manufacturing: Capabilities

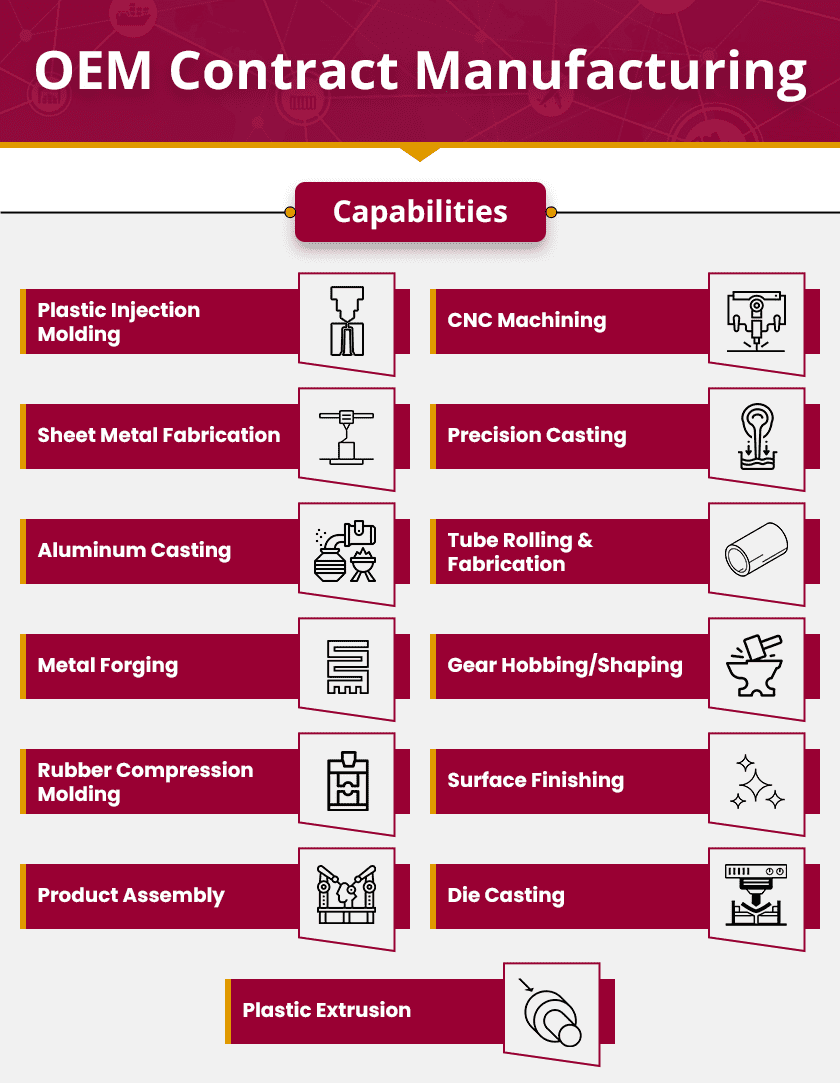

We designed our OEM contract manufacturing program to meet the needs of your product catalog, assisting with ideal material and manufacturing process selections to optimize your product and budget. Our core capabilities and material options include the following:

| PROCESS | MATERIAL |

|---|---|

| Plastic Injection Molding | Acrylonitrile butadiene styrene (ABS), polyamide (PA), polycarbonate (PC), polyethylene (PE), polypropylene (PP), and polystyrene (PS) plastics |

| Rubber Compression Molding | Chloroprene (CR), ethylene propylene diene monomer (EPDM), and nitrile butadiene rubber (NBR) |

| CNC Machining | Aluminum, brass, and steel |

| Sheet Metal Fabrication | Aluminum and steel |

| Tube Rolling and Fabrication | Metals (aluminum and steel) and plastics |

| Precision Casting | Aluminum, steel, and zinc |

| Aluminum Extrusion | Aluminum |

| Die Casting | Multiple material options |

| Metal Forging | Aluminum, iron, and steel |

| Gear Hobbing and Shaping | Aluminum and steel |

| Plastic Extrusion | Polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) |

| Surface Finishing | Plating and powder coating |

| Product Assembly | Multiple material options |

OEM Contract Manufacturing: Volumes

Source International has built a reputation as a company you can trust to simplify your supply chain management efforts for streamlined operations. We pride ourselves on maintaining a 98% on-time delivery rate with a <0.25% defect rate so that you receive your products on spec and on time, every time. Once we understand your expected yearly throughput and see your product specifications, prints, and any samples, we’ll start creating a custom quote to fit your budget and project requirements. During manufacturing, our in-country technicians and engineers will document production and assembly processes and ensure that we’ve met all product specs and necessary certifications for full quality assurance prior to shipment.By leveraging our highly developed infrastructure, factory automation, and our capacity for high-volume production, we offer you the economy of scale you need to enhance profits. We produce and deliver more than 20,000 containers each year of high-quality products. Source International can help you increase throughput while simultaneously lowering costs and actually improving quality with high-value, tight-tolerance products.

Our team includes engineers, quality technicians, product managers, and more for complete production management from engineering through to in-house quality testing in our world-class testing laboratories. With offices in the U.S., China, and Vietnam, Source International offers the ideal balance of global access and local control, with reliable, scalable offshore OEM contract manufacturing and accountable product management services for peace of mind.

OEM Contract Manufacturing: Cross-Cultural Team

Our cross-cultural liaisons efficiently oversee and manage:

- Product specifications and development

- Intellectual property

- Prototype samples

- Scheduling

- Manufacturing processes

- Quality assurance

- Product testing and inspections

- Order deliveries

OEM Contract Manufacturing: Cloud Portal

From our user-friendly cloud portal, authorized users can securely access information in real time related to:

- RFQs

- Pricing

- Product specifications

- MSDS

- Order history and status

- Audits and inspections

- Certifications

Finally, as part of our commitment to human rights, workplace safety, ethical behavior, social responsibility, and environmental awareness, we finish our SIS program with a stringent Supplier and Employee Code of Conduct and related audits. We ensure that extensive training goes into providing employees with the required skills for code compliance.